How to avoid poor contact of wiring harness terminals?

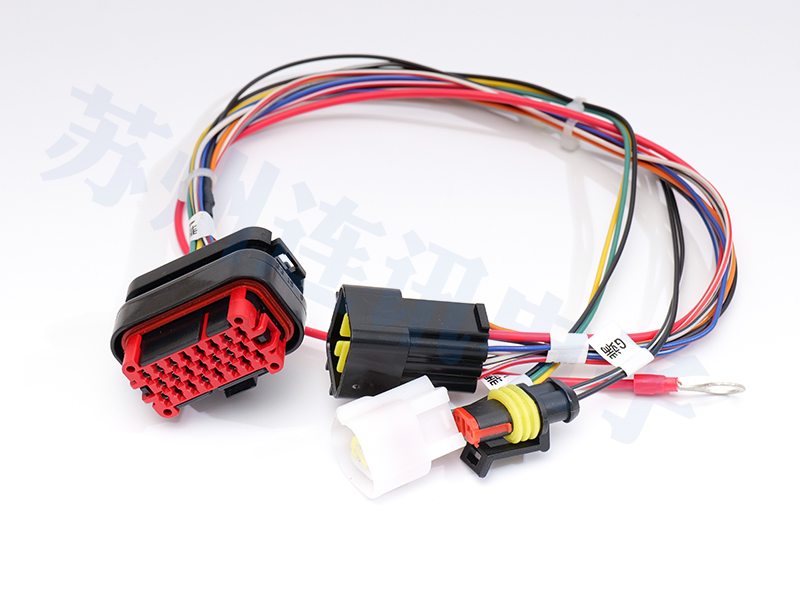

Suzhou Lianxun Electronics specializes in producing customized wire harnesses, mainly including industrial wire harnesses, electronic communication wire harnesses, vehicle wire harnesses, and medical wire harnesses. In electrical systems, terminal blocks are key components that connect various electrical components. However, due to various reasons, poor contact may occur in the wiring terminals, which not only affects the normal operation of the electrical system but may also pose safety hazards. Therefore, how to avoid poor contact of wiring terminals has become an important issue.

1、 Reasons for poor contact of wiring harness terminals

1. Loose terminals: Due to vibration, temperature changes, and other reasons, the wiring terminals may become loose, resulting in poor contact.

2. Oxidative corrosion: Prolonged exposure to air can easily oxidize the surface of the terminal block, forming an oxide film that affects the contact effect.

3. Dust and dirt: Dust and dirt may adhere to the wiring terminals, causing poor contact.

4. Mechanical damage: During installation or maintenance, the wiring terminals may be mechanically damaged, affecting the contact effect.

How to avoid poor contact of wiring harness terminals?

2、 Measures to avoid poor contact of wiring harness terminals

1. Regular inspection: Regularly inspect the electrical system, including the fastening of wiring terminals, surface oxidation, etc., and promptly identify and handle problems.

2. Anti loosening measures: Anti loosening measures should be taken at the connection of the terminal block, such as using spring washers, to ensure a firm and reliable connection.

3. Anti oxidation measures: For wiring terminals exposed to air for a long time, anti oxidation measures can be taken, such as applying anti oxidation agents, to extend their service life.

4. Cleaning and maintenance: Regularly clean and maintain the electrical system, remove dust and dirt, and ensure the cleanliness and good contact of the wiring terminals.

5. Standardized operation: During installation or maintenance, it is necessary to strictly follow the specifications to avoid mechanical damage to the wiring terminals.

Avoiding poor contact between wiring harness terminals is an important measure to ensure the safety and stability of electrical connections. Through regular inspections, anti loosening measures, anti oxidation measures, cleaning and maintenance, and standardized operation, it is possible to effectively prevent poor contact of wiring terminals and ensure the normal operation and safety of the electrical system.

Recommend

-

-

QQ Zone

-

Sina Weibo

-

Renren.com

-

Douban